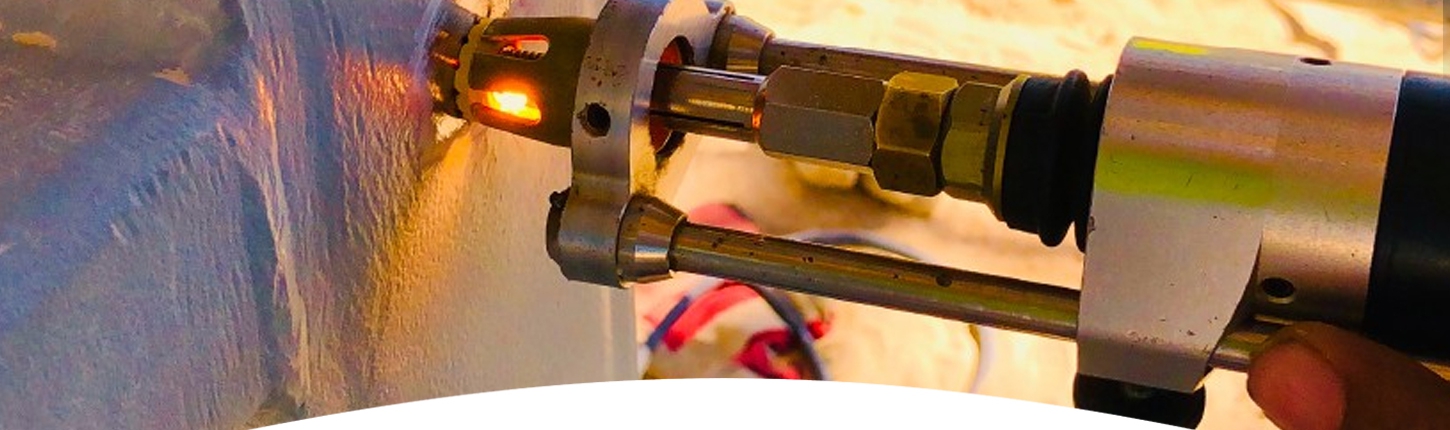

Weld quality assurance from Omega

The blue area results from oxidation at a corresponding temperature of 600 °F (316 °C). This is an accurate way to identify temperature, but does not represent the HAZ width. The HAZ is the narrow area that immediately surrounds the welded base metal.

Many distinct factors influence the strength of welds and the material around them, including the welding method, the amount and concentration of energy input, the weldability of the base material, filler material, and flux material, the design of the joint, and the interactions between all these factors.

For example, the factor of welding position influences weld quality, that welding codes & specifications may require testing both welding procedures and welders using specified welding. To test the quality of a weld, either destructive or nondestructive testing methods are commonly used to verify that welds are free of defects, have acceptable levels of residual stresses and distortion, and have acceptable heat-affected zone HAZ properties. Types of welding defects include cracks, distortion, gas inclusions porosity and non-metallic inclusions, lack of fusion, incomplete penetration, lamellar tearing, and undercutting.

GB Welding Procedure for you in Chennai

We can write/develop all required welding procedures (WPS), procedure qualification records and advise on all relevant codes, standards and specifications.

Assist in training and qualification of welders/ welding operators to various codes, standards and customer specification.

Quality Documentation Reviews:

Produce QA/QC documentation and provide working instructions for any welding application, no matter how large or small.

On Site Services, General Help & Advice:

Our services are available as a ‘hands-on’, or a more formal ‘technical engineering’ approach; you decide which one, or we’ll be happy to offer you both. The scope includes:

Material Selection, Post weld heat treatment and Testing:

Advice on material selection and behavioral effects of composition variation with materials.

Development of Post welds heat treatment methodology and procedure for complex materials, metallurgy and geometry etc.

Mechanical testing for welding qualifications and for investigative purposes.

Material analysis and corrosion testing.

Metallurgical investigation.

Investigations and Analysis:

Investigation of weld ability problems and failure analysis.

Training Services:

Preparation of customized training modules an arranging training at customer premises.