Toshon Welding Machine Supply in Chennai

Toshon Welding Machine Supply In Chennai

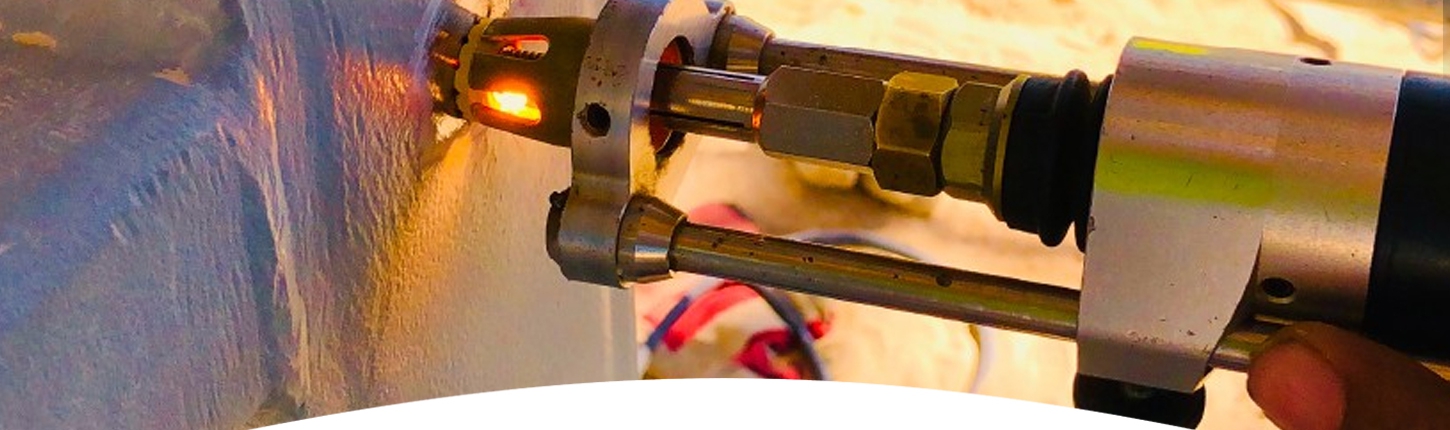

Toshon Welding Machine Supply in Chennai – Omega Cutting & Welding Service, we’ve constructed an unparalleled notoriety for mechanical advancements that address client issues. We have practical experience in multi-process units for Toshon, MIG and TIG welding. Our far reaching scope of practical gear is intended for simple operation and upkeep, versatility and unwavering quality – even in the greatest conditions. We try to reach the highest quality and reliability of machines produced by us, fast and high-quality delivery of the machines, service, selling support and counselling.

Contact us today to explore our range of welding products and experience unparalleled welding solutions tailored to your needs. Let’s forge a strong bond of excellence in welding together. Contact us for more information: +91 93612 86530